Focus on BÜRKERT Flowmeters

Valves Online are one of the largest online companies offering entire solutions to all your valve application needs. As an official distributor of the German manufacturer ‘Bürkert’ we can offer their enormous range of flow, level, pressure and temperature controllers/transmitters.

Over the next few months, we will be giving you an insight into the wide range of products we can offer from Bürkert.

Today we want to start with flow metering devices, specifically designed to meet all your flow metering and switching needs. Because of the variety of devices and principles we have listed typical solutions to your area of application.

Electromagnetic Flowmeter (EMF)

|

|

|

Insertion EMF |

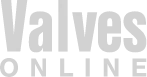

Full Bore EMF |

- Suitable for CIP cleaning

- Nominal diameters up to DN2000

- Low wear thanks to lack of moving parts

Electromagnetic flowmeters (EMF) have been used for continuous flow measurement in industrial applications for many years. They are ideally suitable for liquids with an electrical conductivity greater than 5 μS/cm. In addition to water and waste water, other contaminated liquids are typical areas of application.

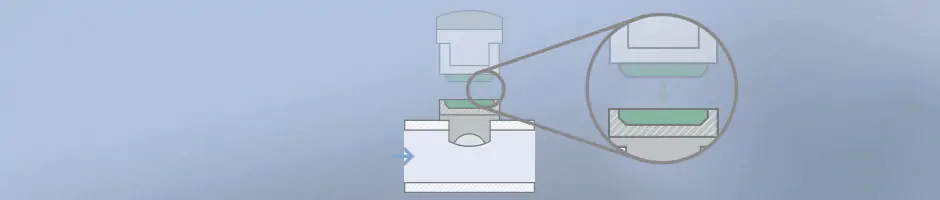

The underlying measuring principle of the EMFs is based on Faraday's law of induction. The coils of the flowmeter generate a magnetic field orthogonal to the flow direction. According to Faraday's law of induction, a conductive liquid passing through the magnetic field induces a current between the two electrodes, which can be used to measure the voltage. The higher the flow velocity, the higher the induced voltage. This voltage signal is converted into a standard signal (e.g. 4 - 20 mA or P) by the integrated electronics.

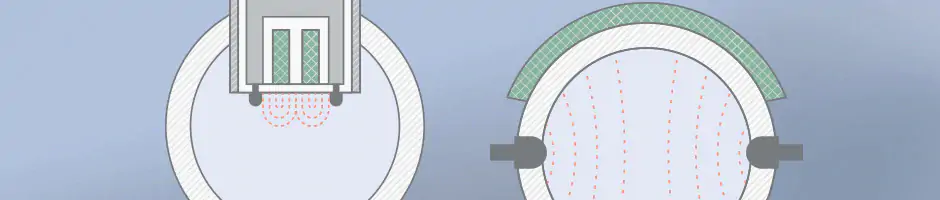

Paddle Wheel

- Ideal for neutral and solid-free liquids

- Nominal diameters up to DN400

- Simpler installation thanks to fitting system

When liquid flows through the pipe, the paddle wheel rotates and produces pulses where the frequency it transmits is proportional to the flow rate.

Used to accurately measure and dispense predetermined volumes of water or other solid-free compounds. Flowmeters, also known as insertion flowmeters or inline flowmeters, provide relatively high accuracy with low cost and simple installation.

Flow Transmitter

- Continuous measurement

- Different variants available

- Numerous combination possibilities of flow transmitters

Contact our technical sales team to discuss all flow transmitter needs

Email: [email protected]

Phone: 01822 855600

Flow Fittings / Armature

- Universal

- Wide range of process connections for the sensor fittings

- PVC, PP, PVDF, PE, stainless steel and brass available

Contact our technical sales team to discuss all flow transmitter needs

Email: [email protected]

Phone: 01822 855600

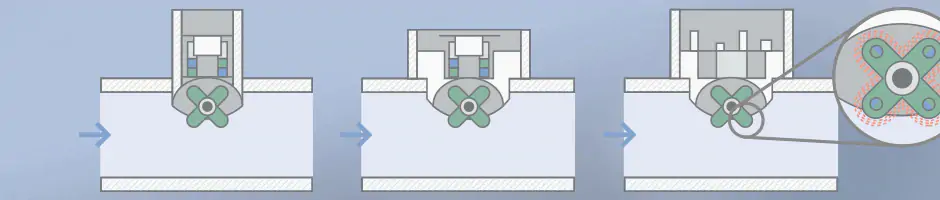

Oval Gear (Positive Displacement)

- Ideal for high-viscosity media such as adhesive or oil

- Also suitable for high pressures

- Fitting system allows for simple installation

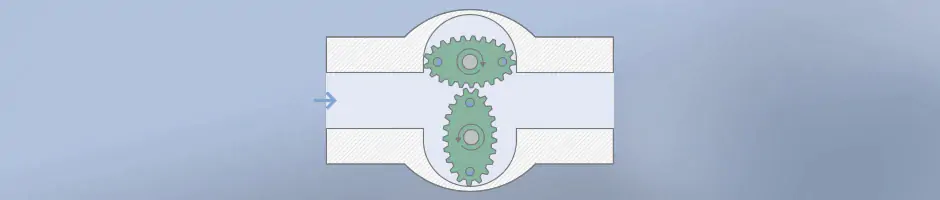

The measuring element of an oval gear meter consists of two toothed precision oval wheels which are driven by the fluid passing through the unit. The number of revolutions is an exact measure of the volume.

known for accuracy and longevity in the field. This simple, robust design means the oval gear meter is stable in harsh environments and maintains accuracy regardless of the liquid temperature, changes in viscosity, or pulsating flow.

Switch/Flow

- Ideal for Controlling the flow of liquids

- High functional reliability under challenging conditions

- Simple setting of switch points

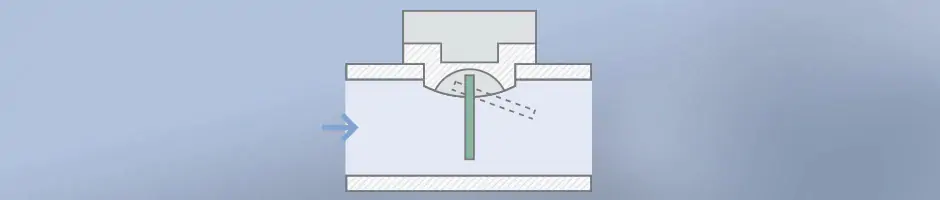

INLINE flow sensor/switch is specially designed for use in pure and water resembling fluids, free from air bubbles and magnetizable particles, to monitor minimum/ maximum values of flow. The sensor/switch can be quickly and easily connected together by a Quarter-Turn. This device indicates the presence of a flow in the pipe by switching the Reed contact contained in the electronic module. The switching points Min./Max. for rising and falling velocities can be set with a screw within a defined range.

The flow control switch is suitable for liquids as normally open or normally closed contact. The switching process is triggered by a reed contact. The flow moves the magnet, which is located on a rocker bar. The switching point is adjustable. The flow control switch works reliably even under difficult conditions with low pressure drop. The switching process is well repeatable.

Ultrasonic flow meter

- Low maintenance thanks to contactless measuring principle

- Measuring span of water-based liquids of 1:250

- No flow-settling section required

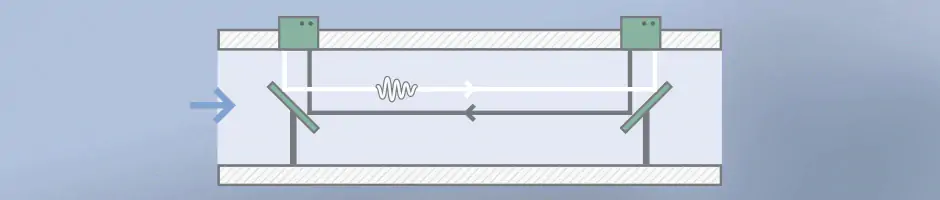

Ultrasonic flowmeters use sound waves to determine the velocity of a fluid flowing in a pipe. At no flow conditions, the frequencies of an ultrasonic wave transmitted into a pipe and its reflections from the fluid are the same. ... When the fluid moves faster, the frequency shift increases linearly.

Ultrasonic flowmeters are commonly applied to measure the velocity of liquids that allow ultrasonic waves to pass, such as water, molten sulfur, cryogenic liquids, and chemicals.

FLOWave (Surface Acoustic Waves)

- Ideal for very low flow velocities

- Impervious to vibrations, magnetic or electric effects

- Flexible installation position possible

based on SAW (Surface Acoustic Waves) technology and is mainly designed for applications with the highest hygienic demands. This is achieved by using: - suitable stainless steel materials - a measuring tube free of any wetted parts except for the actual tube - the ideal outer hygienic design. FLOWave offers a range of integrated functions, including the advantages of flexibility, ease of cleaning, compact dimensions, lightweight, easy installation and handling, and is compliant with numerous standards. Optimal measurement results can be achieved with homogeneous, air and solid free liquids. Integrated viscosity compensation can be used for higher viscous liquids. Gas and steam cannot be measured; however, their flow does not have any negative effect on the device or its operation. Other liquids flowing through again afterwards are measured correctly as before.

Rotameter

- Suitable for translucent liquids and gases

- Nominal diameters starting from DN10

- Can be equipped with limited value contacts

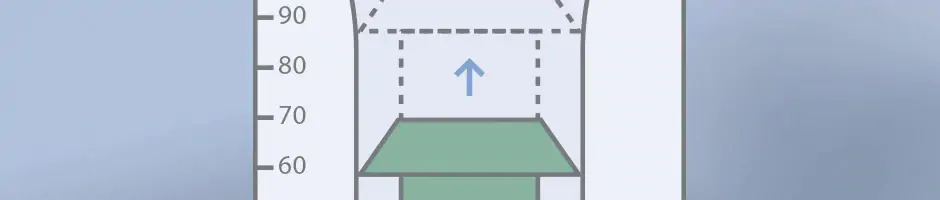

If a medium with sufficient flow rate flows from bottom to top through a vertically inserted measuring tube, then the floated element is raised so far, and the equilibrium between the lift strength of the medium itself and the weight of the floated element is adjusted. Since the average flow rate is proportional to the flow quantity per time unit, the determined equilibrium corresponds to the flow volume. Flow meters with solenoid floated elements can be equipped with limit value contacts.

Please contact our technical sales team with your flowmeter requirements and projects for quality and competitive solutions.

Email: [email protected]

Phone: 01822 855600

See the full Bürkert range below: